#statusMessage#

Do you want to start the compare now?

It's hard to imagine modern medicine without technical aids. From the imposing CT tube to the delicate microchip that is transplanted into the skin: Impressive technologies are used in the medical field. One of these is sensors that measure a wide range of parameters with the utmost precision, literally saving lives. However, professional measurement technology is essential for them to function reliably. In the following, dataTec SPEKTRUM shows which technology is already being used in the healthcare sector and which technologies are currently being researched.

How do sensors help to make everyday hospital life easier and safer? Which technologies are already supporting medical professionals today? And which technologies that do not yet exist are researchers currently working on so that they can become a reality tomorrow and help people? Join us on a journey through the day in a hospital.

The first rays of sunshine come through the window and the ward manager has just started her shift. She checks how many beds are currently available. This is made possible by sensors integrated into the beds, which measure the occupancy rate in real time and transmit it wirelessly. This also makes follow-up processes such as bed preparation after patients have been discharged more efficient and frees up nursing staff for real emergencies. A Berlin-based IoT company has already successfully tested the process and is now working on integrating the data even better into hospital information systems.

The morning is all about ward rounds for the doctors. It is practical for them to know the patients' vital signs in advance. It's good that the doctors can rely on the nursing staff. Using sensors incorporated into the clothing, which are as thin as paper, values such as blood pressure, heart rate and body temperature are automatically measured in advance and analyzed in real time in the offices. If there are any abnormalities, the doctors are informed immediately and can act quickly. In times of an increasing shortage of specialists, this is a considerable support.

Around midday, the treatment rooms are filled with details. An oncologist wants to find out how her patient's tumor has developed over the last few days. To do this, she uses a smartphone to read data from a sensor chip that has been implanted directly into the affected tissue and measures its oxygen content. Medical technicians at the Technical University of Munich have developed this technology to reliably monitor tumors that are difficult to operate on or slow-growing. The chip is barely the size of a thumbnail and can be used on numerous parts of the body.

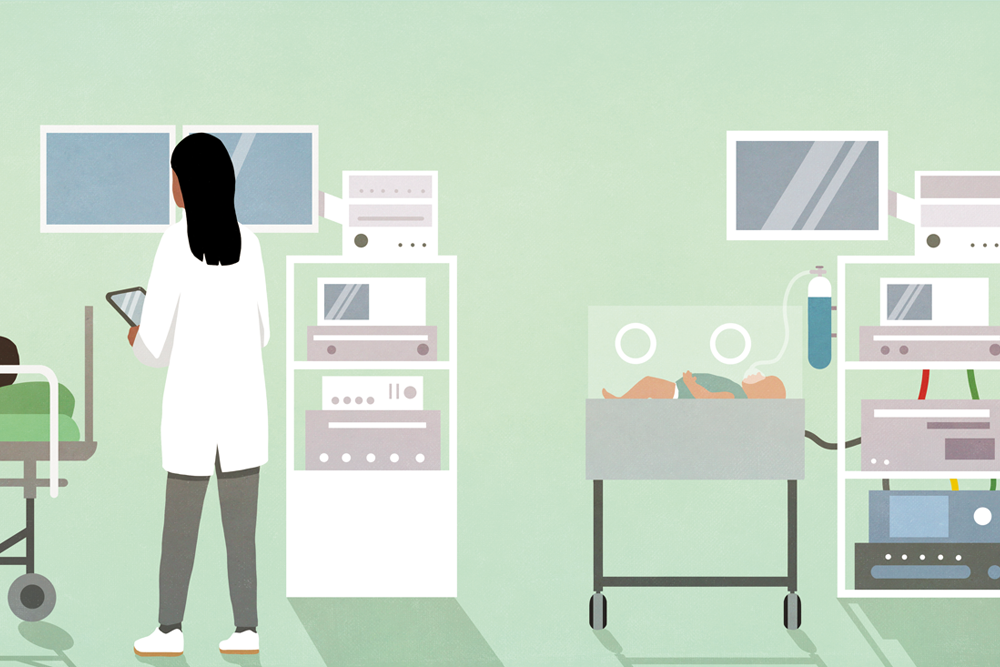

Meanwhile, things are hectic on the children's ward: a premature baby is born and has problems breathing. With the help of an intelligent patch that analyzes the baby's weak breathing, the ventilation measures that are immediately initiated can be ideally adapted to the premature baby's own breathing thanks to real-time data. The lightweight and stretchable patch with over 36 bending sensors is simply stuck to the baby's chest - painlessly and without invasive surgery. Studies have shown that this procedure leads to significantly better long-term results. Despite all the excitement, this is a ray of hope for the new parents and the staff.

Maximum concentration in the operating room: the surgeon is scheduled to perform brain surgery. To do this, the patient's skull must first be opened – a critical point, as even the smallest injuries could have fatal consequences. What's more, many of the bone saws still in use today have not been technically modified for decades. Not so in this hospital: a saw with sensors provides detailed information about the bone thickness to be cut through during the cutting process and its special design protects the soft tissue. Thanks to its minimal cutting gap, the wound heals particularly quickly afterwards, which shortens the entire healing process, saves the surgeon time and puts less strain on the patient overall.

The operation starts well, but after a few minutes there is a sudden loud beeping. „Something's wrong,“ announces the surgical assistant with a tablet in his hand. All the measured vital signs and data from the instruments are collected on it. There is even a live camera image of the operating theater and a current X-ray image of the patient. This is because the clinic has an intelligent monitoring system that can be used to network the entire operating theater. Hundreds of sensors supply their data, which is processed by a computer and can even provide an initial diagnosis in many cases using artificial intelligence.

In another operating theater, the monitoring system has also just been activated: "Suspected bleeding wound," calls the assistant. The evaluation of sensor data has revealed that a surgeon has aspirated more fluid from the abdominal cavity during an operation than was rinsed in. This indicates a bleeding wound that needs to be stopped immediately. An assistant taps on the tablet and suddenly the position of the table changes, the light becomes brighter and ECG lines appear on the monitor: the fully digitized operating theatre has set itself up for the next steps. How lucky for the patient that everything happened so quickly.

Where is the open wound? This is what needs to be found out. The surgeon grabs a pair of futuristic-looking glasses with lots of cameras and puts them on. They are equipped with augmented reality and virtually mark the injured area. The surgeon is then shown in his field of vision where he needs to start suturing the wound. He can even show or hide individual organs and skin layers, as the patient's body has been scanned beforehand and saved as a complete 3D model. After a few minutes, the bleeding is stopped – and the procedure is already recorded in the digital patient file.

While the first patients are already looking forward to dinner in the late afternoon, the nursing staff are still a long way from finishing work. In the treatment room, they are putting a sensor-equipped orthosis on the foot of a patient with an ankle injury. The pressure-sensitive sensors ensure that the woman, who has fallen down the stairs, does not put too much strain on her foot and overstretch her ligaments out of overconfidence. If it does happen, an alarm sounds on her smartphone. According to a Fraunhofer IWU project, this significantly shortens the healing process and minimizes the risk of further damage caused by overconfidence.

Meanwhile, in another treatment room, a diabetic comes in for a check-up because the young man has recently had a sensor implanted in his upper arm. This automatically measures blood glucose in the subcutaneous fatty tissue and can be read at home via smartphone without the diabetic having to prick himself. All measurement results are automatically stored digitally. This is practical for the doctor looking after the patient, who can now get a quick overview of the patient's state of health with just a few clicks on the computer at the hospital and optimize their therapy individually.

Night has fallen, but the hospital can't rest. An ambulance arrives at the emergency room with a motorcyclist who has had an accident. He has severe chest pains, but the doctors present cannot agree on the exact nature of his injuries. That's why the newest member of the team comes into play: an artificial intelligence that can analyze X-ray images. After just a few minutes, the result is clear: there is a fracture, but a pneumothorax is considered unlikely. Further examinations confirm this assumption and the doctors are happy to be able to treat the patient accordingly without having missed anything.

The operating principle of sensors can essentially be reduced to the following interaction: The sensor provides an electrical variable, for example voltage, current or resistance, and the evaluation electronics convert this into the parameter to be measured, for example pressure, brightness, flow or temperature. However, precise measurement and testing technology is required in order to be able to rely on the sensor systems. From the development of the sensors to regular maintenance.

Measuring means comparing – and in the modern world, this means not only physical quantities, but also digital data. Many familiar technologies from our everyday lives would be inconceivable without sensors and the appropriate measurement technology. Even standardized processes that require constant quality control could not be implemented without sensors. After all, just one incorrect measured value can have fatal consequences – and, in case of doubt, cost human lives.

As you can see, the applications for sensor devices are diverse - but they only work as reliably as they have been set up for their intended use. In addition to correct installation and commissioning, this also includes regular maintenance and calibration. With the measuring and testing technology that you receive from dataTec, you always ensure precise measurement results and thus help to get the best out of the sensor technology.

The dataTec experts will be happy to advise you to help you find the optimum measurement solution for your task and industry.

You are not quite sure yet or have further questions about the products? Do not hesitate to contact us. Whether directly on the phone or via online demo conveniently in front of your screen - our experts are there for you.