#statusMessage#

Do you want to start the compare now?

Automation with thermal imaging technology has proven to be a reliable solution for quality control in various industries. Whether in industrial safety areas such as automotive, packaging, food processing or in the manufacture of electronic components. Thermal imaging cameras make it possible to detect defects early and without contact, resulting in lower costs and higher customer satisfaction.

Efficient inspection in the automotive industry with thermal imaging technology.

New vehicles are subjected to a series of individual and automatic quality checks. In the automotive industry, thermal imaging technology is a reliable solution for the quality control of hard-to-reach components such as rear window heaters, seat heaters, exhaust flaps and air conditioning outlets. Functionality is checked with a thermal image on a screen in front of the vehicle. This allows the inspector to determine whether the part on the vehicle is working as intended based on changes in the thermal profile.

Applications in practice:

Wärmebildkameras (A50/A70/Axxx) mit Bild-Streaming.

Smart-Sensor-Wärmebildkameras (A50/A70/Axxx).

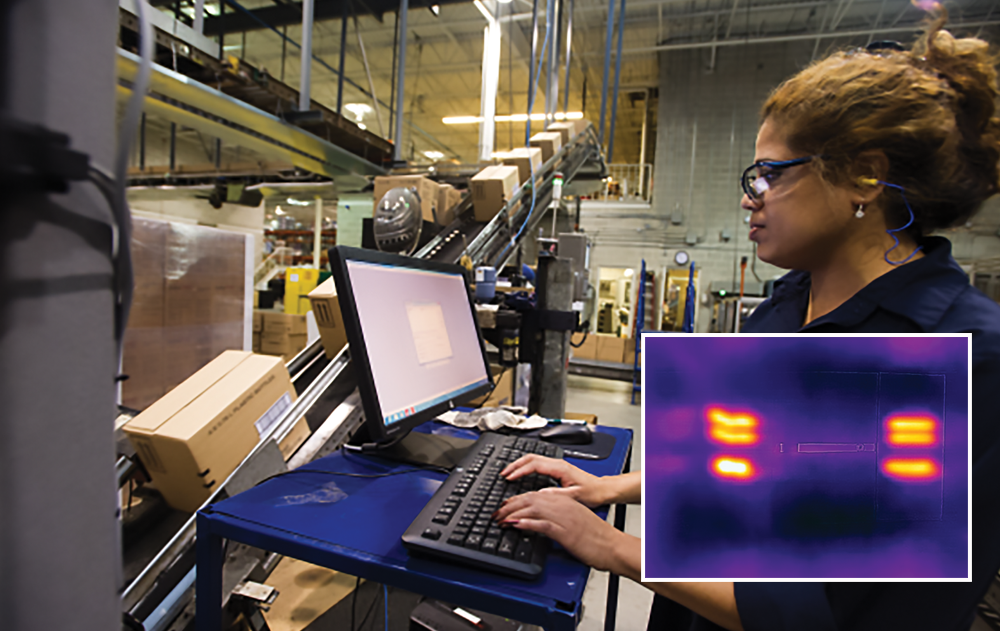

Improved quality control through thermal imaging technology in the packaging industry.

In the packaging industry, thermal imaging technology is an effective solution for quality control of sealed packaging, adhesives and coatings. Thermal imaging cameras can be installed to check predefined areas on the cardboard flaps to see whether hot melt has been applied as intended, in what quantity and at what temperature.

Applications in practice:

Wärmebildkameras (A50/A70/Axxx) mit Bild-Streaming.

Smart-Sensor-Wärmebildkameras (A50/A70/Axxx).

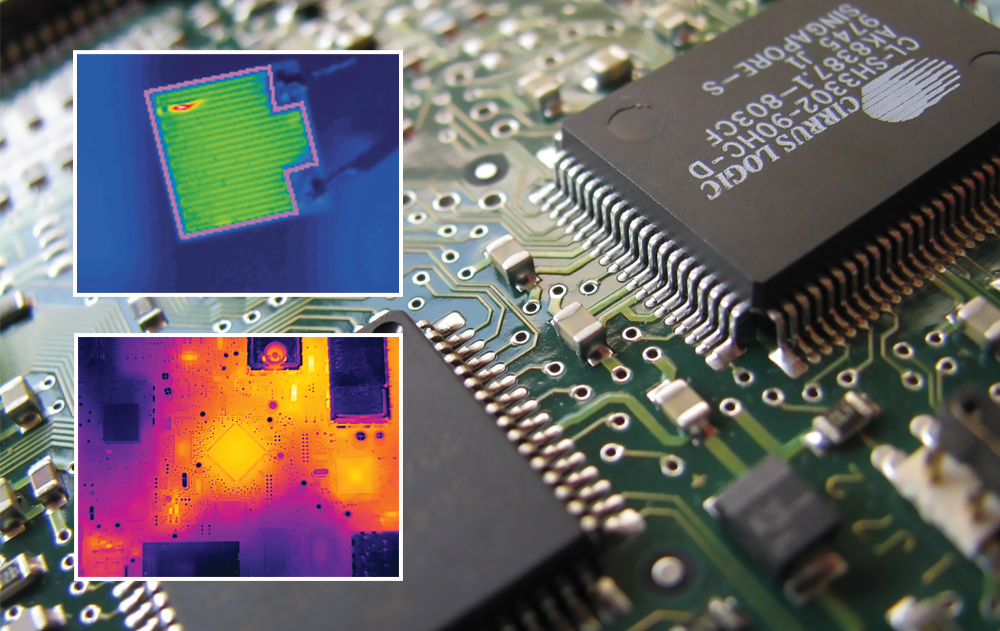

Reliable quality control is essential for electronic components in order to meet customer expectations. Many components are small and difficult to inspect. Thermal imaging technology offers a non-contact, reliable and effective means of quality control for printed circuit boards, transistors, diodes and other components. One example is the use of thermal imaging cameras to check the temperature of electronic components in smartphone production.

Applications in practice:

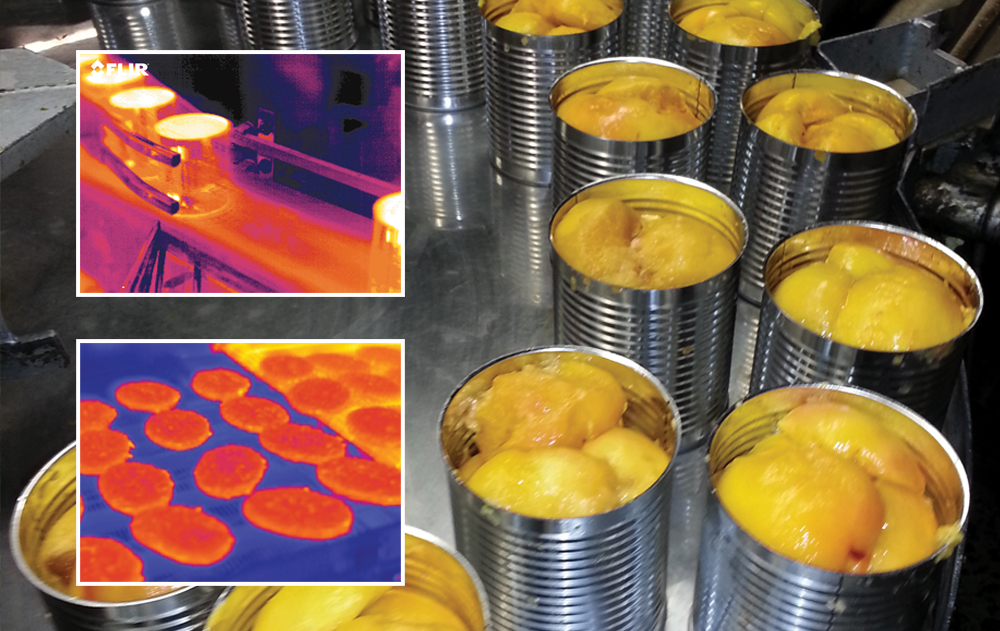

Food quality is a top priority in food processing. Thermal imaging technology is a reliable solution for ensuring the quality of processed food. The cameras function as intelligent and non-contact sensors for in-depth inspections and measure the temperature of machines, chilled products and cooked food at the end of the processing process and in storage.

Applications in practice:

Wärmebildkameras (A50/A70/Axxx) mit Bild-Streaming.

Smart-Sensor-Wärmebildkameras (A50/A70/Axxx).

Thermal imaging technology is therefore an important part of modern quality control in various industries. FLIR Automation offers a wide range of thermal imaging cameras and other solutions tailored to the specific needs of each industry. Learn more about how FLIR Automation can help you optimize your quality control processes and increase your productivity.

As a partner of Teledyne, we offer you a free and professional initial consultation with our experts. Our certified thermographer will analyze your equipment and systems to identify potential problems and provide you with the optimal solutions for your Flir Automation product needs.

What are you waiting for? Arrange a consultation now and benefit from our many years of expertise. Contact us today and let us help you find the right solutions for your company.

You are not quite sure yet or have further questions about the products? Do not hesitate to contact us. Whether directly on the phone or via online demo conveniently in front of your screen - our experts are there for you.