#statusMessage#

Do you want to start the compare now?

#statusMessage#

Do you want to start the compare now?

With the increasing importance of renewable energies in the wake of climate change, solar energy is moving further into ...

The complexity of military radios and the often harsh weather conditions have a negative impact on the reliability of ra...

Automation with thermal imaging technology has proven to be a reliable solution for quality control in various industrie...

In diesem exklusiven Whitepaper erfahren Sie, wie Sie mit der richtigen Messtechnik arbeiten: ✔ Sie realisieren ein Test...

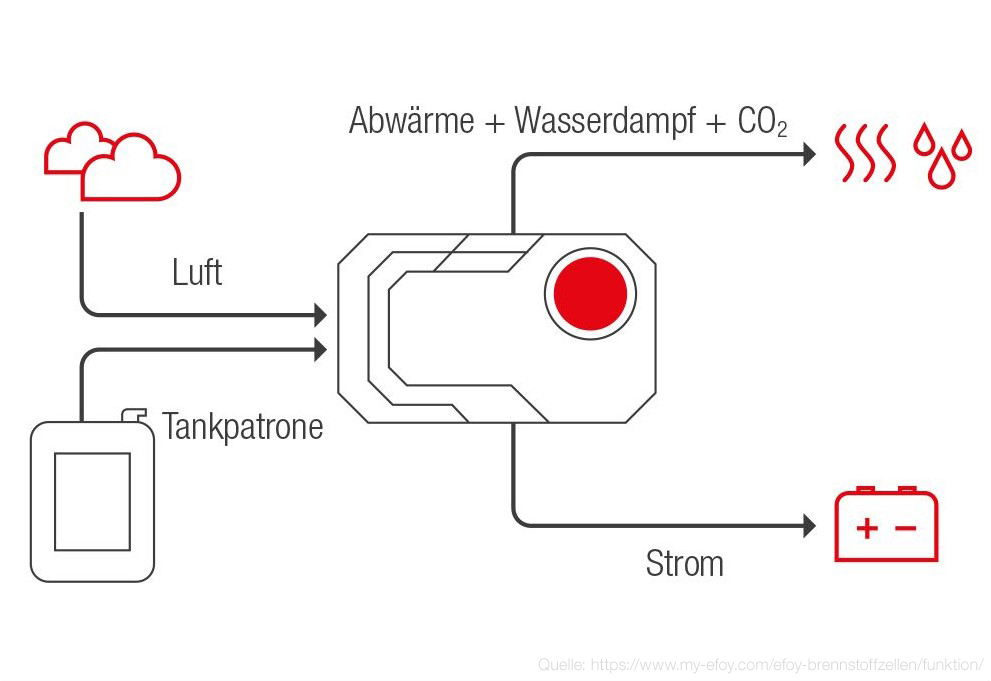

DMFCs (Direct Methanol Fuel Cells) are modern representatives of energy systems for environmentally friendly power generation. Methanol is converted into electrical energy.

An active DMFC has complex control and regulation technology designed to achieve optimum efficiency. The development of the control electronics requires universal tools such as oscilloscopes, high-resolution multimeters and current measuring transformers.

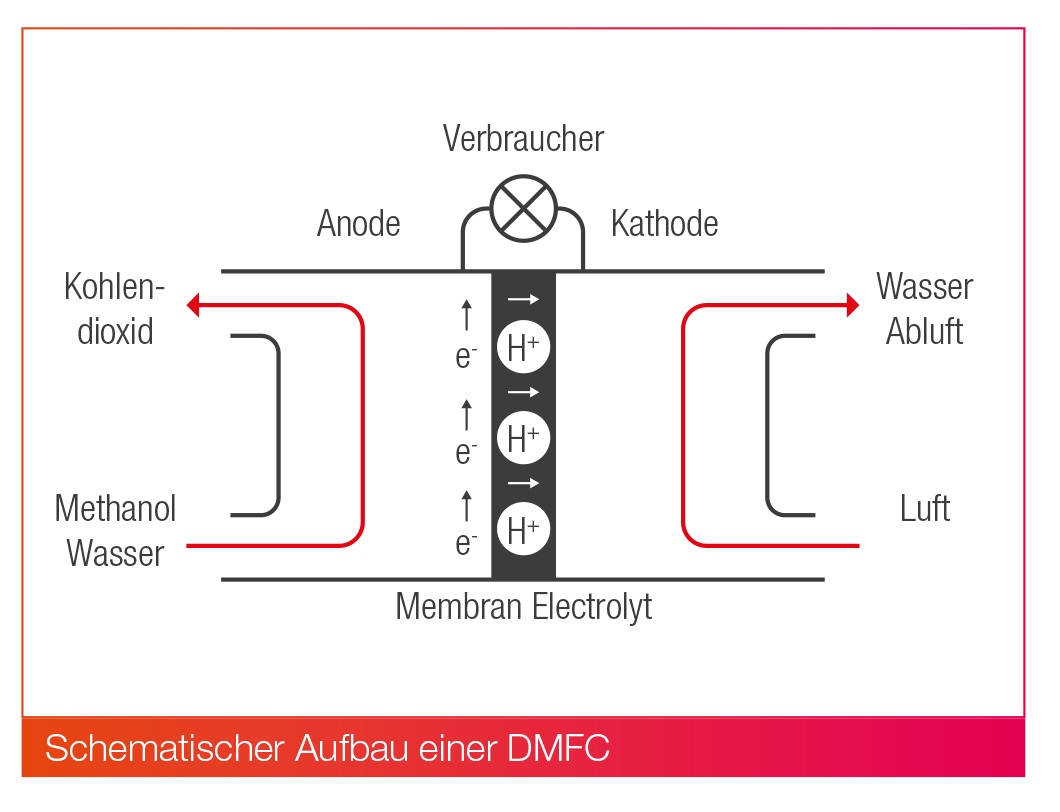

In a DMFC, the fuel methanol (as a mixture of methanol and water) is converted directly into electrical energy through an electrochemical reaction with added oxygen, i.e. without first producing hydrogen from it. Electrons flow from the anode to the cathode via an external circuit and thus generate usable electricity. A DMFC can supply electrical energy for as long as methanol is supplied.

One of the key features of DMFCs is their ability to operate at low cell temperatures, enabling quick starts. As methanol can also be easily transported in fuel cartridges, this fuel cell technology is particularly suitable for mobile applications. In the form of power packs, DMFCs supply power to distant measuring stations and video surveillance systems, robots, portable chargers or mobile homes, for example.Current developments are aimed at miniaturizing DMFCs so that, for example, medical hearing aids can be operated with methanol ampoules.

In addition to the actual fuel cell, in which the methanol is converted into energy, an active DMFC system requires a large number of peripheral components, e.g. metering pumps or compressors, as well as intelligent control and regulation technology. The efficiency of the overall system and thus the usable electrical power depends on the control of the operating parameters. A microprocessor accesses the corresponding control routines and sensors with the respective input variables for current, voltage, fill level, temperature etc. Depending on the area of application of the DMFC, it may also be necessary to raise the voltage of the fuel cell to the level of the target application. Voltage converters are used for this purpose.

Measurement technology optimizes DMFCs in terms of their performance, efficiency, operating time and compactness. Load simulation is carried out with an electronic load. The development of power and control electronics requires universal tools such as oscilloscopes, high-resolution multimeters, probes and current transformers.

The oscilloscope supports electronics development with measurements for power analysis, switching losses, harmonics or input parameters, among other things. Current consumption curves, e.g. of sensors or converters, can be precisely visualized with the appropriate probes. High-resolution digital multimeters (DMM) are also used for reproducible current measurements, for example to assess the electrical parameters of actuators (coil, motor, etc.) or to characterize the output variables of a sensor and its transfer function.