#statusMessage#

Do you want to start the compare now?

The DIN VDE regulations govern the electrotechnical regulations as defined by DGUV V3 (accident prevention regulations for electrical systems and equipment). They form the legally binding basis for the safe installation, manufacture and operation of electrical systems, devices and equipment. Modern measuring and testing devices are available for efficient and safe performance of the electrical tests prescribed in the VDE standards, with which the necessary work steps can be simplified and test procedures automated. An overview of relevant VDE regulations and useful application examples for standard-compliant implementation with suitable measuring and testing devices can be found here.

During the course of 2021, the new standards VDE 0701 (EN 50678) and VDE 0702 (EN 50699) were introduced. These are derived from the previously applicable standard DIN VDE 0701-0702 by adapting it to European directives and splitting it into two parts.

The European directives are being adapted as national standards in all European member countries of the CENELEC (Comité Européen de Normalisation Électrotechnique) with the general aim of unifying standards in Europe and promoting the single market.

The transition period for the scope of the old standard VDE 0701-0702 ends on 16 December 2022 (VDE 0701) and 21 September 2023 (VDE 0702), respectively.

Amendments to DIN VDE 0701-0702:

We provide you with basic knowledge, show you how to apply it successfully in practice and carry out measurements with you in accordance with the relevant standards.

The VDE standards are part of the DIN standards (German Institute for Standardisation). The standard designation therefore contains both a DIN number and a VDE number, e. g. DIN 57100 VDE 0100. The abbreviation DIN VDE 0100 is commonly used. VDE regulations are valid nationally but may also be harmonised at European level. In this case, the designation follows DIN EN (European standard).

The VDE body of standards is subdivided into nine groups (DIN VDE 00xx to DIN VDE 08xx):

Group 0: General principles and terminology

Group 1: Energy plants

Group 2: Energy conductors (electrical wires and cables)

Group 3: Insulating materials (insulators, superconductors, etc.)

Group 4: Monitoring technology (fire detectors, radiation protection, etc.)

Group 5: Machines and converters (e. g. batteries)

Group 6: Installation material and switchgears (for electrical installations)

Group 7: Utility and work equipment (e. g. household appliances, power tools, lights)

Group 8: Information technology (telecommunications and antenna systems)

DIN-VDE 0100 – Testing of stationary electrical systems and installations: Stationary electrical equipment includes, for example, lighting systems, built-in refrigerators, cookers, instantaneous water heaters / boilers, air-conditioning systems, etc. and electrical installations in buildings such as plug sockets, power lines, data lines, sensors, etc.

DIN-VDE VDE 0701 and VDE 0702 (EN50678 and EN50699) – Testing of mobile electrical equipment: These are, for example, PC workstations, printers, monitors, card readers, telephone systems, fax, photocopiers, scanners, stereo systems, microwaves, water boilers, coffee makers, multiple sockets, soldering irons, extension cables, hand-held drills, laboratory equipment, table/upright lamps, etc. This also includes private devices that are used or operated in the company.

DIN-EN60204-1 (corresponds to VDE 0113-1) – Tests on machines, systems and their installations: The electrical equipment of industrial machinery must be inspected regularly in accordance with "Deutsche Gesetzliche Unfallversicherung e. V." (DGUV) Regulation 3 (formerly Berufsgenossenschaftliche Vorschrift (BGV) A3), whereby a distinction is made between stationary and non-stationary installations.

Stationary installations are those that are permanently connected to their surroundings, e. g. installations in buildings, construction site vehicles, containers and on vehicles. These installations are e. g. sockets, power lines, data lines, etc.

Non-stationary systems are characterised by the fact that they are dismantled (disassembled) after use in accordance with their intended use and reassembled (connected together) at the new place of use. These include, for example, installations on construction and assembly sites, temporary structures.

Depending on the company, different equipment and systems are in use. Accordingly, various DIN VDE standards with specific test specifications and requirements for the company apply. As a result, the company subject to the inspection obligation must consider the following issues, among others:

Who may carry out the mandatory inspections?

Depending on the VDE standard to be applied, a defined level of training is required for the person carrying out the inspection. Accordingly, the prescribed electrical inspections must generally be carried out by a "qualified electrician".

A qualified electrician is a person who is authorised to carry out and supervise electrical work on the basis of his or her professional qualifications. In Germany, the basis for this is usually a classic electrical engineering apprenticeship or degree course. Depending on the equipment to be tested or the system and the type of test, an "electro-technically instructed person" or even the user of a suitable measuring and testing device may also be qualified to perform the test.

Investing in the appropriate measurement technology can significantly expand the group of people permitted to act as inspectors and increase the productivity of the company. Personnel and training planning can be organised more economically. In addition, the cost-intensive commissioning of an external service provider to carry out the inspections can be dispensed with.

The DIN VDE standards specify inspection intervals, but only the latest date for the inspection. As a matter of principle, the intervals between inspections shall be such that any defects that arise and must be assumed to exist are detected in good time.

Stationary test equipment VDE

Stationary safety and functional tests for DIN EN 60950, 60335, 61010 For the initial testing of equipment. Enable rapid testing in high-volume production and therefore ideal for routine and series testing.

Test equipment VDE 0701 and VDE 0702 (EN 50678 and EN 50699)

Testing of mobile equipment

For measurements with manual or fully automatic test routines, as recurrent or repair tests according to VDE 0701 and VDE 0702 (EN 50678 and EN 50699) for small mobile devices, extensions and socket distributors, as well as according to DIN VDE 0751 / IEC 62353 MPG for medical devices.

Also includes VDE 0751 - Manufacturer testing and German Medical Devices Act (MPG)

and VDE 0544 - Recurrent and repair tests on arc welding equipment according to DIN VDE 0544-4 / IEC 60974-4

Test equipment VDE 0100

Testing of stationary electrical systems and installations (building inspections)

For initial, recurrent and repair tests according to DIN-VDE 0100 / IEC 60364-6 on power installations with rated voltages up to 1,000 V.

DGUV V3 regulates the intervals and documentation measures for the testing of stationary machines and systems as well as mobile electrical equipment. The inspection intervals are usually between six months and four years. Failure to observe the prescribed inspection measures by companies and public institutions is a criminal offence.

The regular performance of electrical inspections protects against accidents at work and reduces the costs of unforeseen maintenance or servicing measures up to and including unscheduled operational downtimes. In the event of damage, employers' liability insurance associations and insurance companies will only cover the costs incurred if it can be proven that the inspection intervals according to DGUV V3 have been observed and a corresponding inspection report can be presented.

The responsibility for the implementation of the inspection specifications and compliance with the inspection intervals lies with the plant manager or entrepreneur. The test before initial commissioning is usually carried out by the manufacturer of the devices and systems and must be documented accordingly.

Due to their products, companies in the electrical engineering and electronics sector (manufacturers of household appliances and power tools, illuminant industry, mechanical engineering, transformer manufacturers, automotive suppliers, cable manufacturers, etc.) have to carry out fast, efficient routine and series tests according to DIN VDE standards. In order to fulfil the test specifications without having to employ or train special electricians, measuring devices with fully automatic test routines are available. The particularly simple handling and operability – from carrying out a measurement to documenting the test results – enables the user or the appropriately instructed person to carry out the mandatory tests in accordance with the standards. The automated test routine also shortens the testing time, which has a positive effect on the entire production process and its economic efficiency.

Measuring and testing devices with fully automatic test routine can be configured for the respective test in such a way that the test result and its interpretation ("OK" / "not OK") are delivered to you virtually at the push of a button and the required test protocol incl. test sticker is provided.

Here you will find excerpts from our customer magazine SPEKTRUM. You can find the complete issues here.

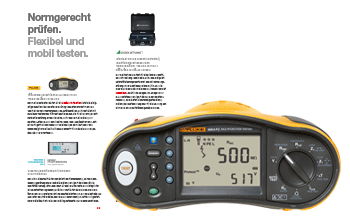

Mobile Gerätelösungen für normgerechte VDE-Prüfungen.

Unsere tragbaren Installations- und Sicherheitstester ermöglichen komfortable, normgerechte Erst- und Wiederholungsprüfungen von elektrischen Anlagen, Maschinen und Geräten.

Prüfung der elektrischen Sicherheit von Geräten mit dem SECUTEST ST PRO.

Der Gerätetester vereinfacht die normgerechte Prüfung von elektrischen Geräten. Dank der aktualisierbaren Firmware sind Sie auf zukünftige Prüfvorschriften und Normänderungen vorbereitet.

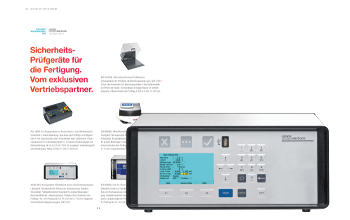

Sicherheitsprüfgeräte für die Fertigung.

Als exklusiver Vertriebspartner von SPS electronic bieten wir Ihnen multifunktionelle Sicherheitstester für die schnelle Funktionsprüfung in der Produktion oder im Entwicklungs- und QS-Labor.

Netzqualitätsanalyse und Fehlersuche in der Netzversorgung.

Erfahren Sie, wie Sie Netzstörungen und den Energieverbrauch von Industrieanlagen analysieren und dokumentieren können.

VDE-Sicherheitsprüfung in der Industrie.

Unsere praktischen Multifunktionstester für die Erst- und Wiederholungsprüfung elektrischer Anlagen ermöglichen die schnelle Analyse und effiziente Protokollierung Ihrer Messungen.

You are not quite sure yet or have further questions about the products? Do not hesitate to contact us. Whether directly on the phone or via online demo conveniently in front of your screen - our experts are there for you.