#statusMessage#

Do you want to start the compare now?

#statusMessage#

Do you want to start the compare now?

Our electromagnetic environment is heavily burdened due to the multitude of transmitters and sources of interference pre...

Automated test and measurement systems that are fully connected with instrumentation and test data can significantly inc...

Temperature is one of the most common risk factors in industry. Overheating can disrupt processes, reduce quality or cau...

Electric vehicles are the future - but what happens to the batteries when they can no longer be used in cars? Efficient ...

Mobile handheld industrial cameras for fast and easy localization of leaks in compressed air, gas, steam and vacuum systems. Inspecting your systems for leaks is usually time-consuming and labor-intensive. With these industrial cameras, however, you can begin leak detection during operation with minimal effort.

Learn why detecting leaks in compressed air, gas, steam and vacuum systems as well as partial discharges is so important and how the industrial cameras from Fluke can help you locate them.

Leaks in compressed air, gas, steam and vacuum systems as well as partial discharges reduce production efficiency, equipment availability and ultimately profitability. Although this issue is well known, locating leaks has traditionally been a tedious and time-consuming process. With the ii500 and ii905/ii915 industrial cameras, maintenance technicians can begin inspections as part of their regular maintenance routines, even while systems are operating, and with only minimal training. The arrangement of tiny sensitive microphones integrated into the camera generates a spectrum of sound levels per frequency.

The ii905 displays acoustic images while technicians inspect hoses, fittings and connections for leaks. The arrangement of tiny sensitive microphones integrated into the camera generates a spectrum of sound levels per frequency. Based on these signals, an algorithm calculates an acoustic image known as a SoundMap™, which is superimposed onto a visual image. This SoundMap automatically adjusts to the selected frequency in order to filter out background noise. With the ii915, partial discharges can also be located easily thanks to its extended frequency range. The SoundSight™ technology converts detected sounds into a visual representation.

| ii500 | ii905 | ii915 | |

|---|---|---|---|

| LeakQ™ | Scale (1–10) | Leak size, estimated leak rate and cost | Leak size, estimated leak rate and cost |

| PDQ™ | X | ||

| MecQ™ | X | ||

| Functions | |||

| Wi-Fi | X | X | |

| Frequency Range | 2 to 52 kHz | 2 to 65 kHz | 2 to 100 kHz |

| Detection Range | Up to 50 m* | Up to 70 m* | Up to 120 m* |

| Visible Image Resolution | 0,3 megapixels | 5,0 megapixels | 5,0 megapixels |

| Operating Time | 6 hours | 6 hours | 6 hours |

| Internal Storage | 20 GB (> 5000 images / > 999 videos) | 32 GB (> 8000 images / > 1600 videos) | 32 GB (> 8000 images / > 1600 videos) |

| Tripod Mount | X | X |

* Depending on environmental conditions

The cameras feature an array of numerous ultra-sensitive microphones that detect the position of both sound and ultrasonic waves and thus locate leaks within a detection range of up to 120 meters.

Frequency ranges:

Proprietary algorithms interpret the detected sound as a potential leak. The results are displayed as SoundMap™ and SoundSight™ acoustic images, color maps that are overlaid onto the visual image.

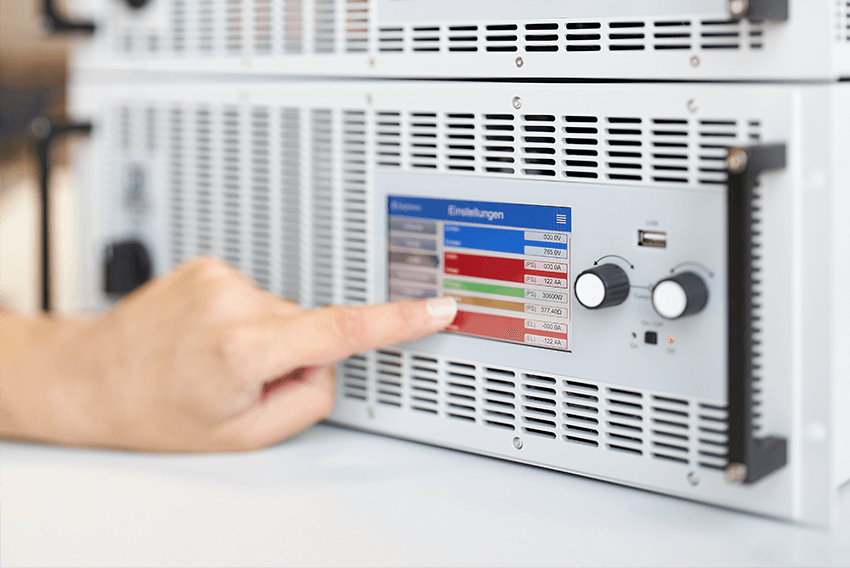

Results are shown on the 7" (17.8 cm) LCD touchscreen either as still images or real-time video. The internal 20 GB memory allows extensive photo and video recording of up to 5 minutes per clip. The camera also displays leak severity and the estimated annual cost.

Enhance your acoustic camera with a precise solution for leak testing without pressurization.

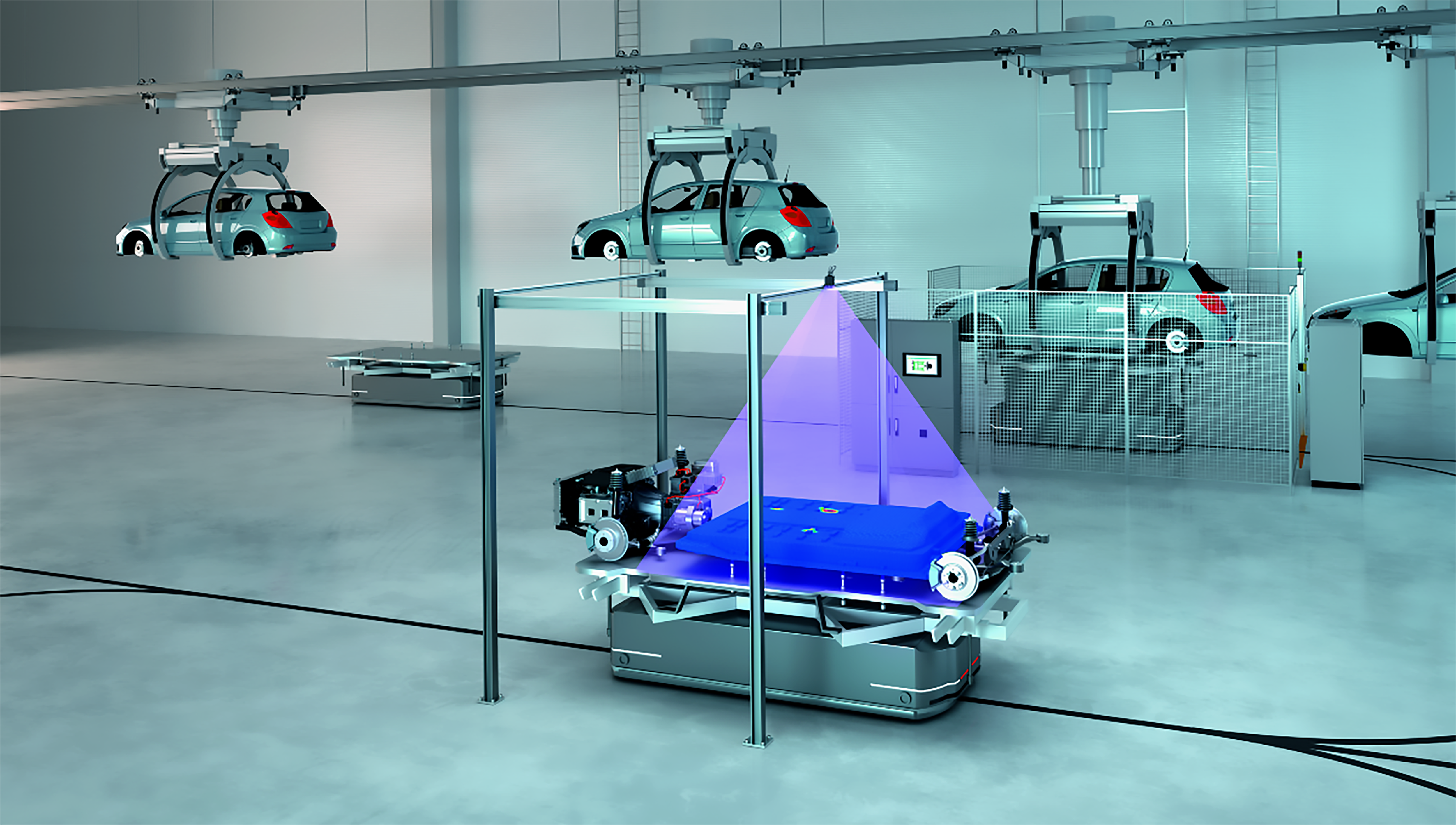

The Fluke SB140 generates a uniform ultrasonic signal that can be visualized by the Fluke acoustic cameras ii500, ii905 and ii915. This allows fast, safe and straightforward localization of leaks in vehicles, aircraft, buildings or enclosures without complex preparation. Ideal for quality control and maintenance in the automotive, aerospace, construction and manufacturing industries.

Take advantage of our convenient bundles:

Combine a Fluke Acoustic Camera (ii500, ii905 or ii915) with the SB140 Transducer and benefit from a special bundle price.

Get everything you need for fast and precise leak detection and tightness testing from a single source.

You are not quite sure yet or have further questions about the products? Do not hesitate to contact us. Whether directly on the phone or via online demo conveniently in front of your screen - our experts are there for you.