#statusMessage#

Do you want to start the compare now?

#statusMessage#

Do you want to start the compare now?

Our electromagnetic environment is heavily burdened due to the multitude of transmitters and sources of interference pre...

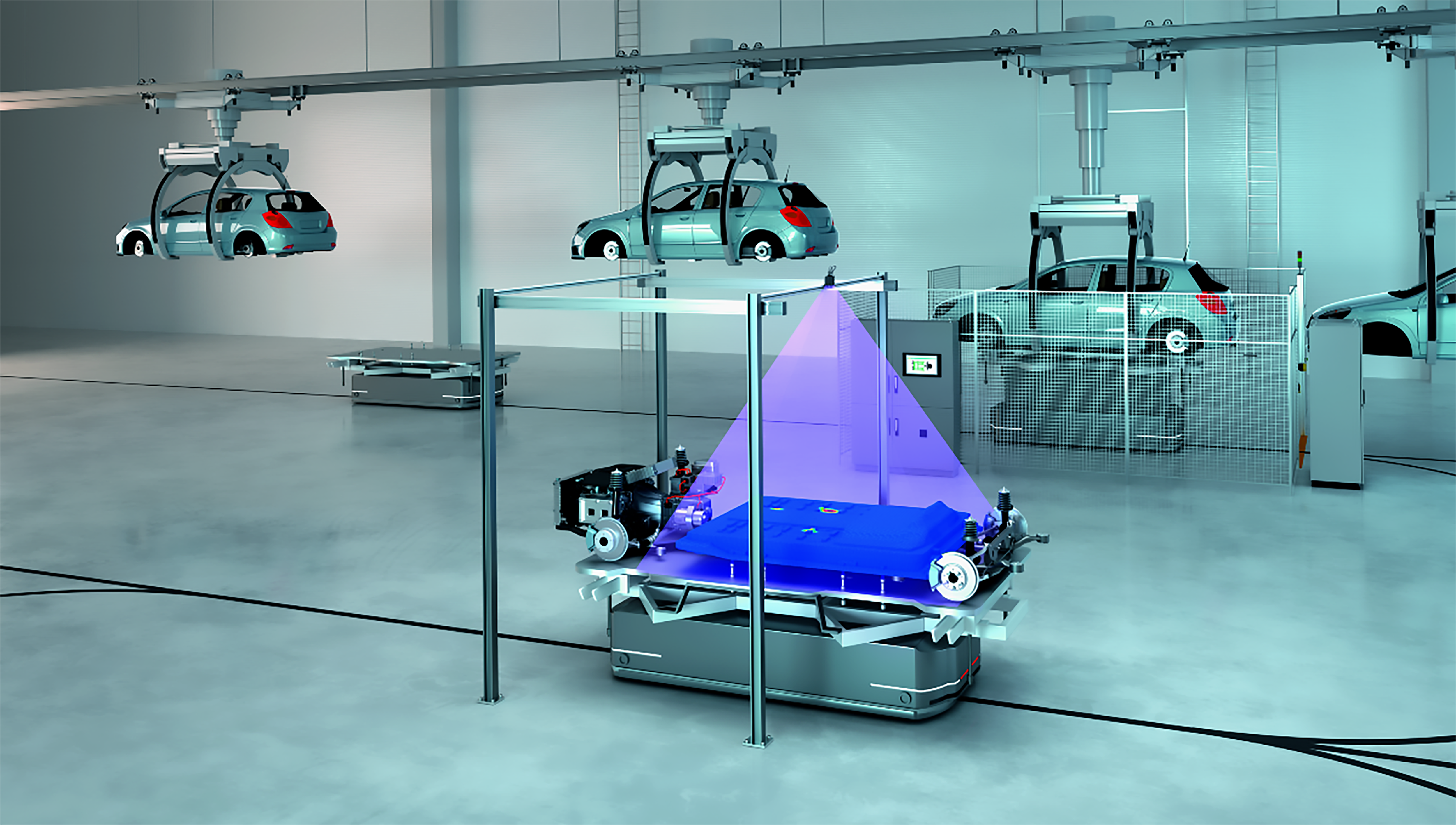

Automated test and measurement systems that are fully connected with instrumentation and test data can significantly inc...

Temperature is one of the most common risk factors in industry. Overheating can disrupt processes, reduce quality or cau...

Electric vehicles are the future - but what happens to the batteries when they can no longer be used in cars? Efficient ...

Manufacturer number: ELR10200-4204U

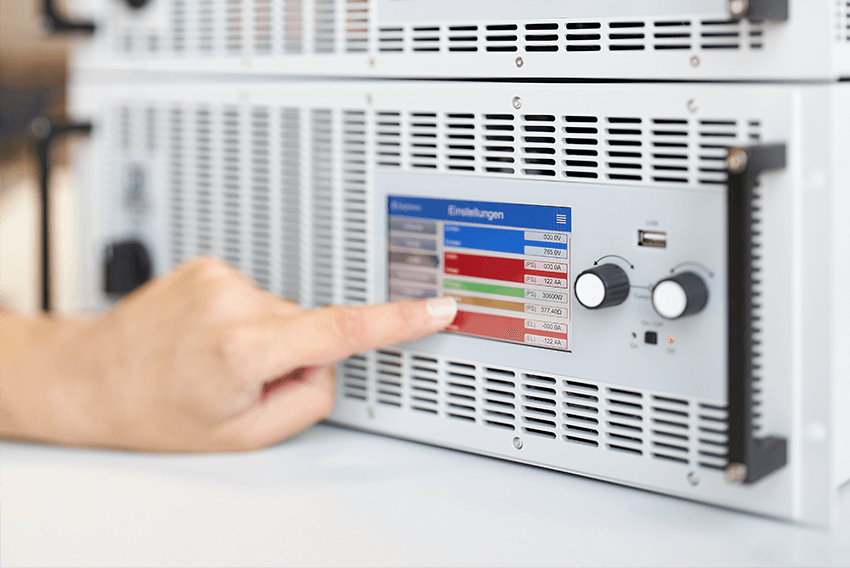

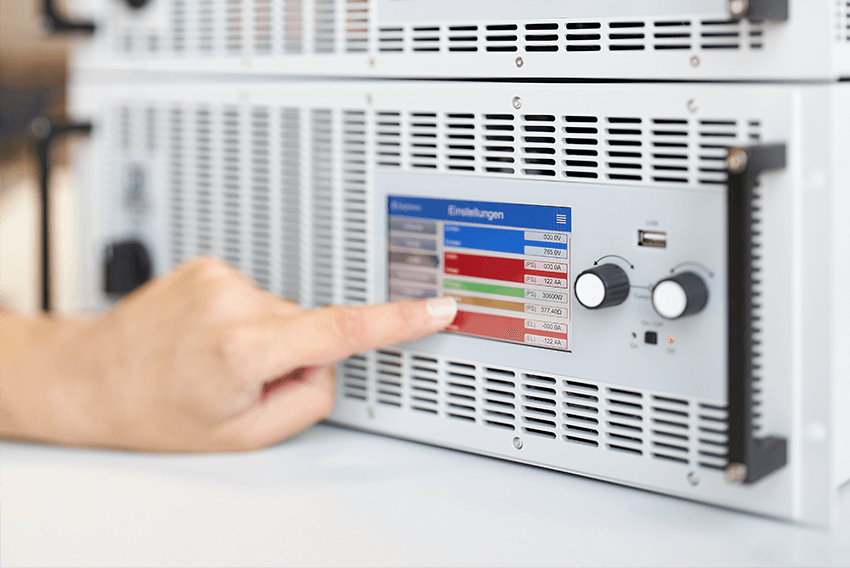

The electronic DC loads of the ELR10000 series with regenerative power supply offer voltage, current and power levels for a wide range of applications. The DC load contains the four typical control types CC, CV, CP and CR. In addition, the FPGA-based control unit offers a function generator, a table control for simulating non-linear internal resistances.

The standard integrated regenerative power supply offers some interesting advantages compared to conventional DC loads, the DC energy absorbed is converted with approx. 95% efficiency and fed back into the power grid, so that energy costs can be saved and complex cooling or ventilation systems can be eliminated because there is hardly any waste heat left arises.

Of course, all common functions of a modern DC load are available. All models offer the four control modes constant voltage (CV), constant current (CC), constant power (CP) and constant resistance (CR). Operation and input of values as well as settings are simplified by the touch panel and the large graphic display provides an overview of setpoints, actual values and the condition of the device at a glance. Using two rotary knobs, setpoints are changed roughly or finely, as well as setting values in the setup.

For remote control via PC and integration into industrial networks such as CAN or Profibus, a range of plug-in interface modules for CANopen, Profibus, ProfiNet, RS232 / 485 or Ethernet / IP are available in addition to the standard integrated USB interface. Further interface types such as ModBus or DeviceNet can be offered on request. Subsequent implementation is simply done via firmware update of the device.

Another feature is the ability to load and save tables and user profiles from USB sticks with a USB host interface on the front of the device, and even to perform data logging without additional hardware. The log data tables in the familiar CSV format can be evaluated and edited on the PC using common tools. This enables the quick and uncomplicated change of test sequence sequences and parameter sets.

Electric vehicles are the future - but what happens to the batteries when they can no longer be used in cars? Efficient ...

Safety, performance, and durability: Test solutions for battery management systems (BMS).BMSs manage batteries and thus ...

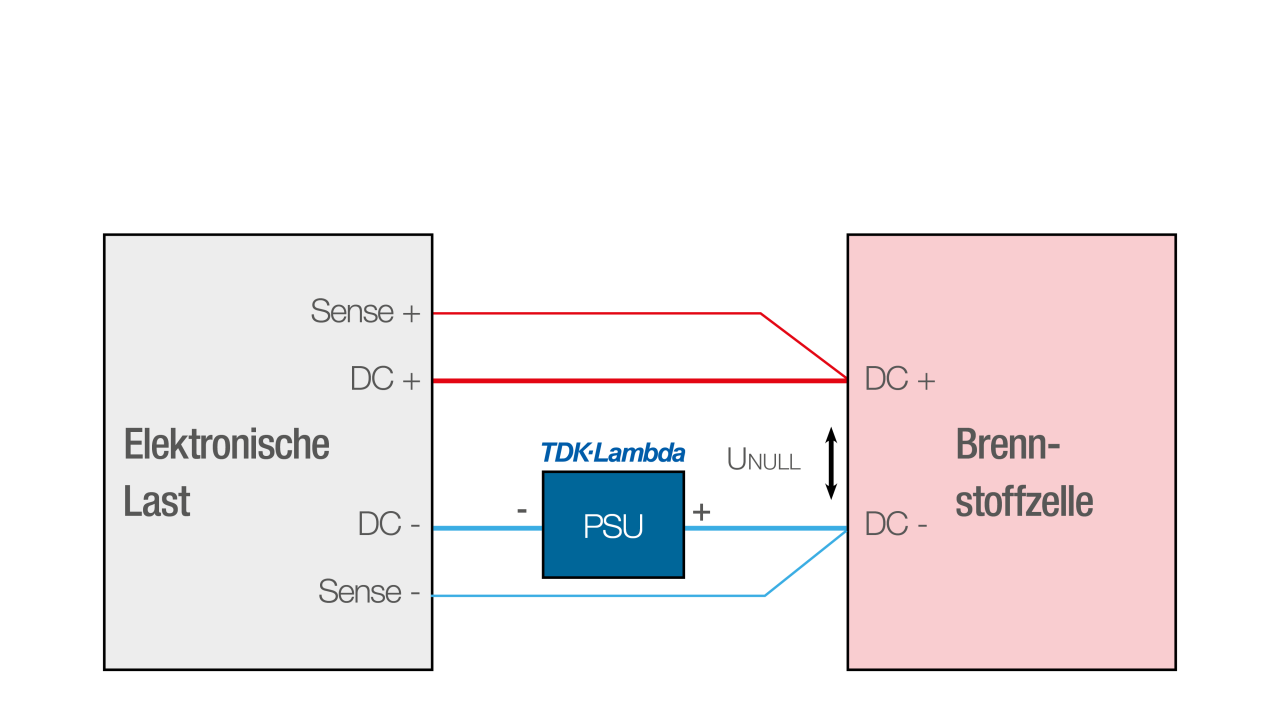

Due to an unavoidable minimum internal resistance - the so-called RDS(on) (minimum on-resistance of the FET between drai...

With the worldwide effort to increase energy conservation and reduce fossil fuel use, electrification is occurring at a ...

With the increasing importance of renewable energies in the wake of climate change, solar energy is moving further into ...

Power supply units are as diverse as their areas of application. What do you personally use your power supply unit for? ...