#statusMessage#

Do you want to start the compare now?

#statusMessage#

Do you want to start the compare now?

How Thermography Enhances Manufacturing. Machine stoppages, component overheating, or electrical faults—unplanned downti...

Disturbances in the power grid often go unnoticed until systems shut down or equipment fails. Regular power quality asse...

In this practical checklist you will learn how to calibrate your measuring and test instruments effectively – simply, ef...

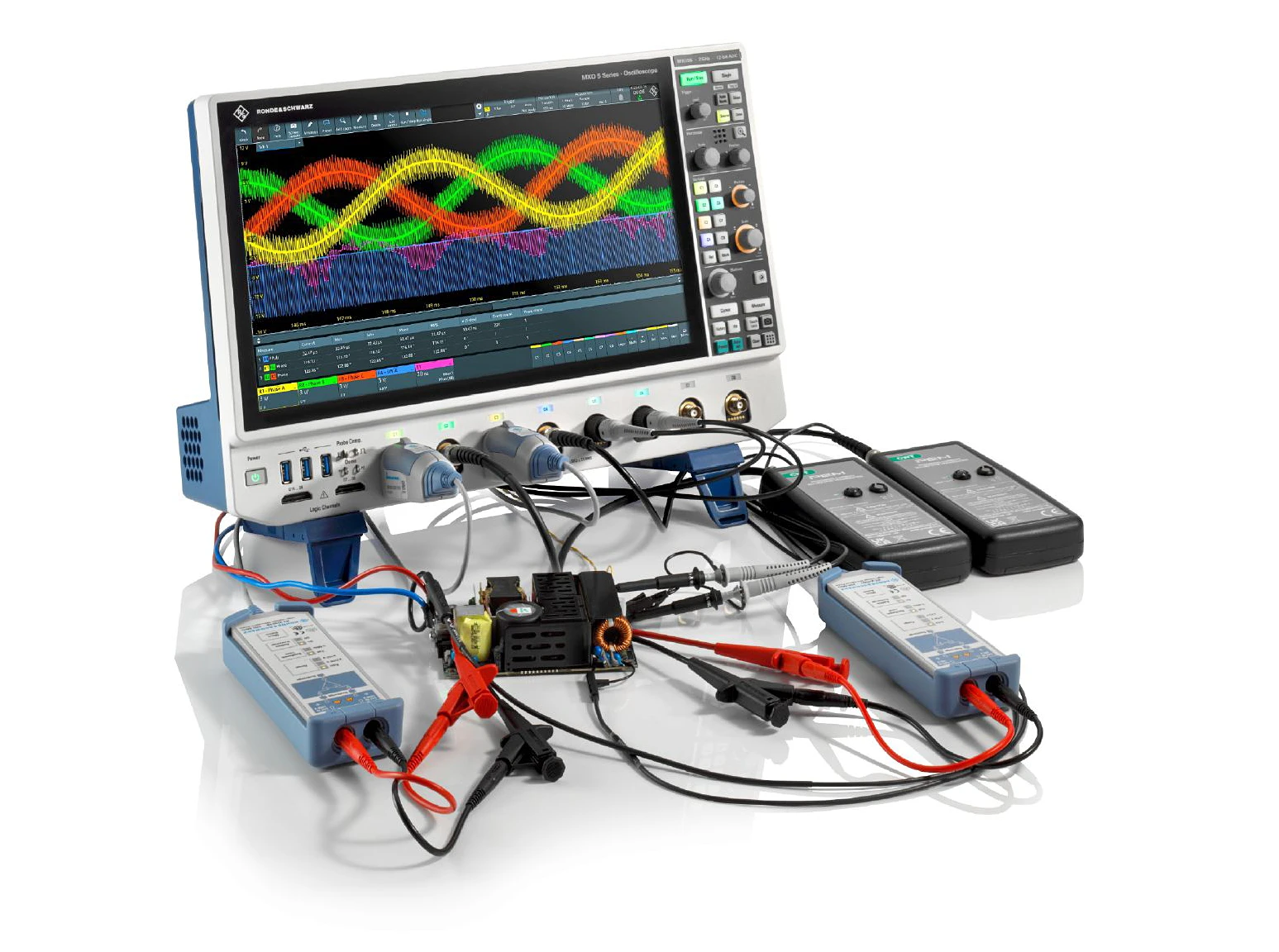

Modern oscilloscopes of the MXO Series from Rohde & Schwarz enable precise analysis and optimization of electric drivetr...

Manufacturer number: 78514-1301

| Article number: | 78514-1301 |

|---|---|

| Focus: | manual, autofocus (contrast/laser) |

| Frame rate (Hz): | 30 |

| Image enhancement technology: | MSX, UltraMax |

| Image memory: | SD card |

| Interchangeable lenses: | Yes |

| Interfaces: | USB |

| Max. field of view (FOV): | 14° x 10° |

| Model: | E86 24°+24° |

| Resolution in pixels: | 464 x 348 |

| Smallest resolution IFOV (mrad): | 0.52 |

| Temperature measuring points: | 161,472 |

| Temperature measuring range: | -20°C to +1500°C |

| Thermal sensitivity (mK): | 50 |

| Weight (kg): | 1 |

The Flir thermal imaging camera E86 of the EXX series helps to quickly uncover thermal problems in electrical and electronic systems, to determine mechanical faults and to carry out preventive maintenance measures.

The object is examined holistically pixel by pixel (each pixel with its own temperature information) and delivers the diagnosis results immediately. The fully equipped one-hand infrared camera with built-in digital camera combines an infrared and real image with the MSX picture-in-picture function : a daylight image is simultaneously superimposed by the radiometric infrared image. In this way, critical problems can be identified even faster and more precisely.

The measurements / thermographic images are saved as JPG, with fully radiometric measurement data per pixel.

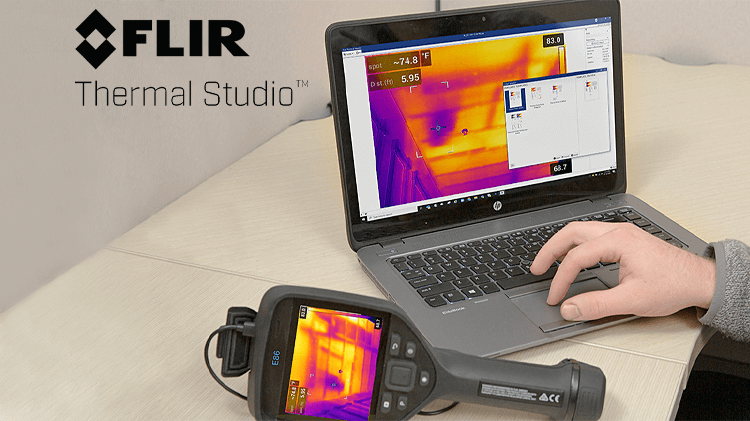

The FLIR E86 supports FLIR Inspection Route and enables integration of the FLIR Thermal Studio and FLIR Research Studio software . FLIR Inspection Routes guides the user along a pre-defined route of inspection points so that they can collect images and data in a structured manner.

Temperature is one of the most common risk factors in industry. Overheating can disrupt processes, reduce quality or cau...

How Thermography Enhances Manufacturing. Machine stoppages, component overheating, or electrical faults—unplanned downti...

Discover our selection of intrinsically safe multimeters, pressure calibrators, milliohmmeters, thermal imaging cameras ...

In order for the inspection of buildings and systems to lead to decision-relevant information, the precise evaluation of...

In the second episode of dataTec unboxed, we present the Ex Pro thermal imaging camera series from FLIR. Discover suit...

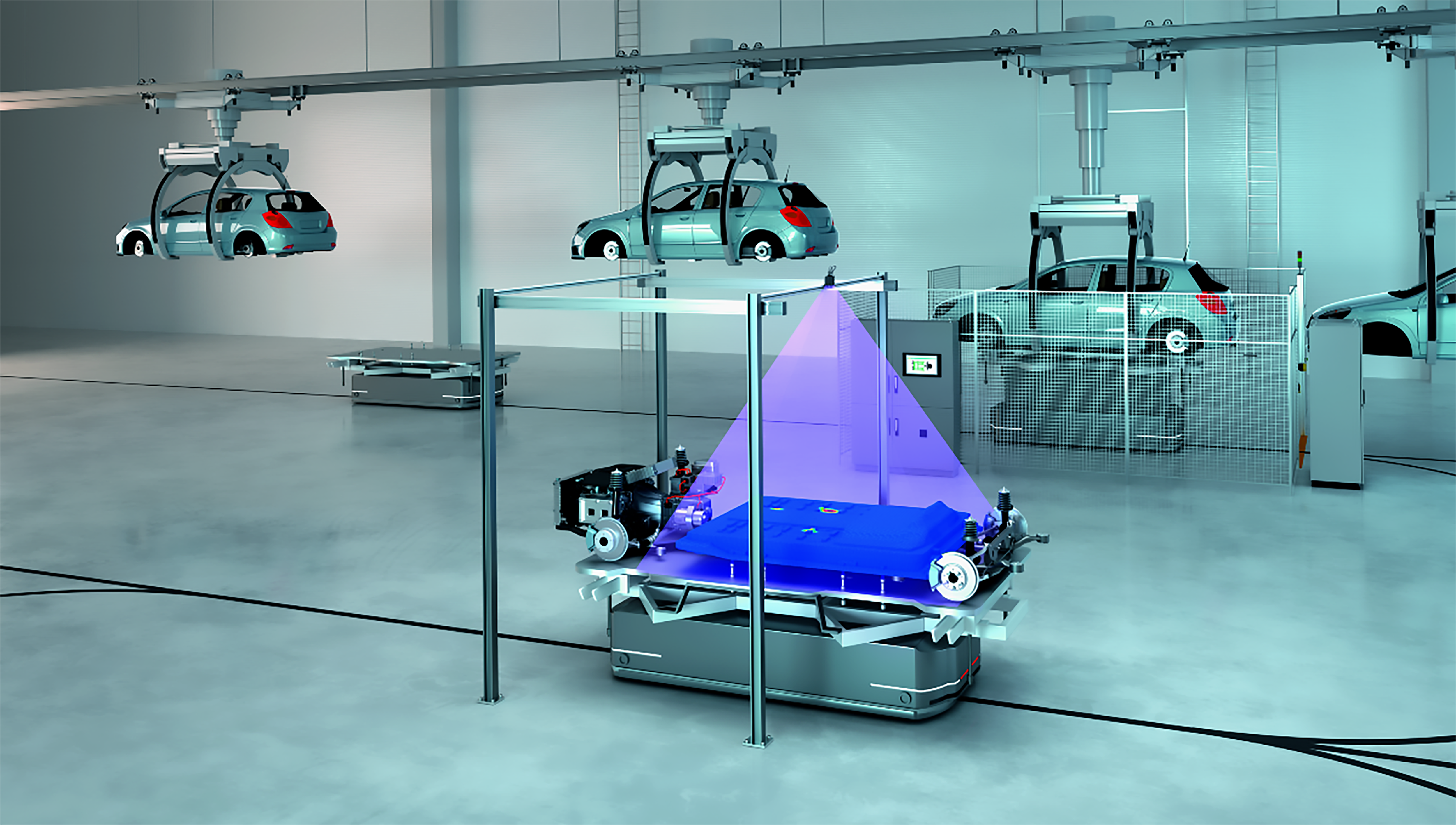

Automation with thermal imaging technology has proven to be a reliable solution for quality control in various industrie...

Thermal imaging cameras are quickly ready for use and easy to operate – directly on site: for example in buildings or pr...