#statusMessage#

Do you want to start the compare now?

#statusMessage#

Do you want to start the compare now?

Our electromagnetic environment is heavily burdened due to the multitude of transmitters and sources of interference pre...

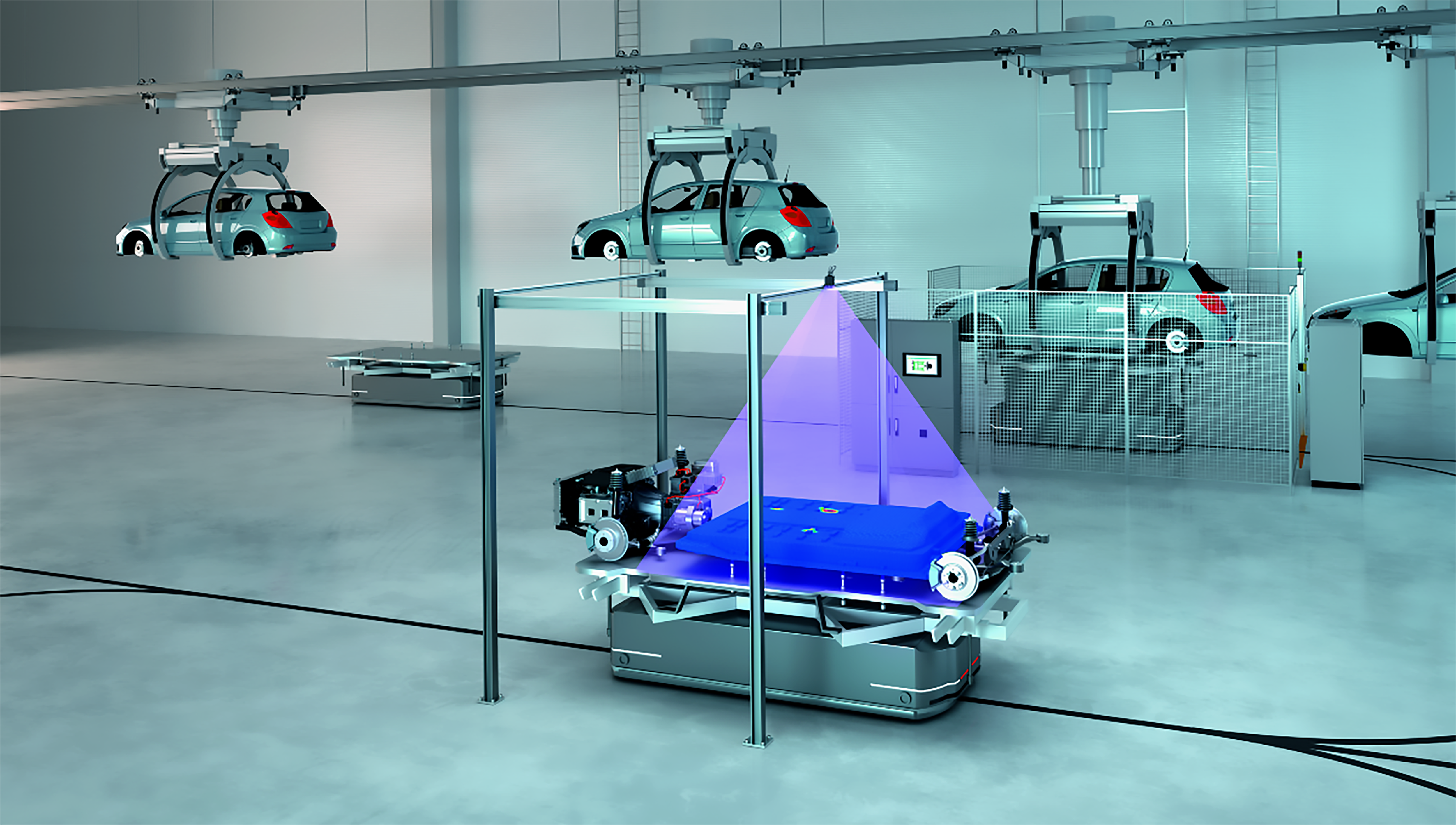

Automated test and measurement systems that are fully connected with instrumentation and test data can significantly inc...

Temperature is one of the most common risk factors in industry. Overheating can disrupt processes, reduce quality or cau...

Electric vehicles are the future - but what happens to the batteries when they can no longer be used in cars? Efficient ...

Manufacturer number: 16502

Options:

| 2-/4-wire: | 4 |

|---|---|

| Article number: | 16502 |

| Dimensions (L x W x H) (mm): | 346 x 320 x 100 |

| Diode test / continuity test: | No / No |

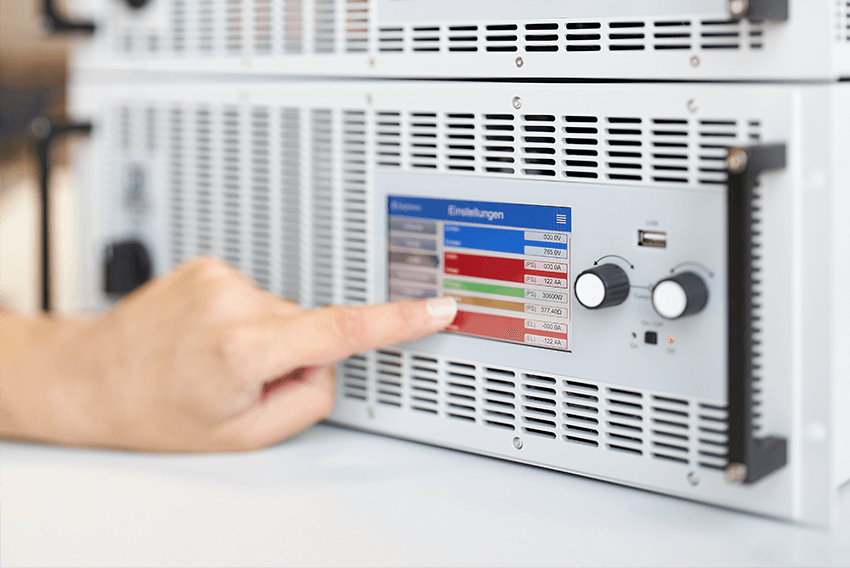

| Display: | 240 x 64 dot-matrix numeric |

| Interfaces: | RS-232, optional GPIB |

| Model: | 16502 |

| Number of positions: | 4.5 |

| Resistance measuring range: | 20 mΩ - 2 MΩ |

| Special features: | opt. GPIB & Handlers |

| Temperature measurement: | Yes |

| Weight (kg): | 4.2 |

DC, pulsed and dry circuit test current output drive modes allow the Chroma 16502 to be used properly when measuring DC resistance for various inductive components (wire coil, choke, transformer winding, etc.), cables, metal contacts (connector, relay switch, etc.) and conductive materials.

The A165014 temperature compensation card with A165015 PT100 temperature probe measures resistance values at ambient temperature, which can be corrected with a thermal coefficient, so that the display outputs corresponding resistance values at other temperatures with the temperature correction function. The temperature increase (Δt) is obtained and displayed by converting the resistance measurements and the ambient temperature using the convenient temperature conversion function. This function is particularly useful for verifying motor windings or coils where the maximum temperature rise when power is applied must be determined.

The pulsed ± function application includes line reactor, switch / relay contact, multi-core, twisted wires, metal foil or conductive material, heat sensitive material (fuse, thermistor sensor) etc. The dry circuit function application includes switch / relay contact, heat sensitive material (fuse, thermistor sensor ) etc. The DC + function application includes highly inductive DUT, e.g. B. Primary coil of transformer measurement (multiple windings) with measurement delay function to avoid the test current generated by the highly inductive DUT during the test period.

A standard RS-232 interface, an optional GPIB & handler interface, extremely fast and stable measurement functions enable the Chroma 16502 to be used for component evaluation in production systems and milliohm measurements in benchtop applications.