#statusMessage#

Do you want to start the compare now?

Power supply units are as diverse as their areas of application. What do you personally use your power supply unit for? And what measurement task do you solve with it? In this article you will find four exemplary areas of application in which power supply units are used: Battery cell simulation, testing of fuel cells, function tests and development of inverters. Learn more about the background of the application, about challenges, but also about their solution. These exemplary applications show you how different and complex measurement tasks can be.

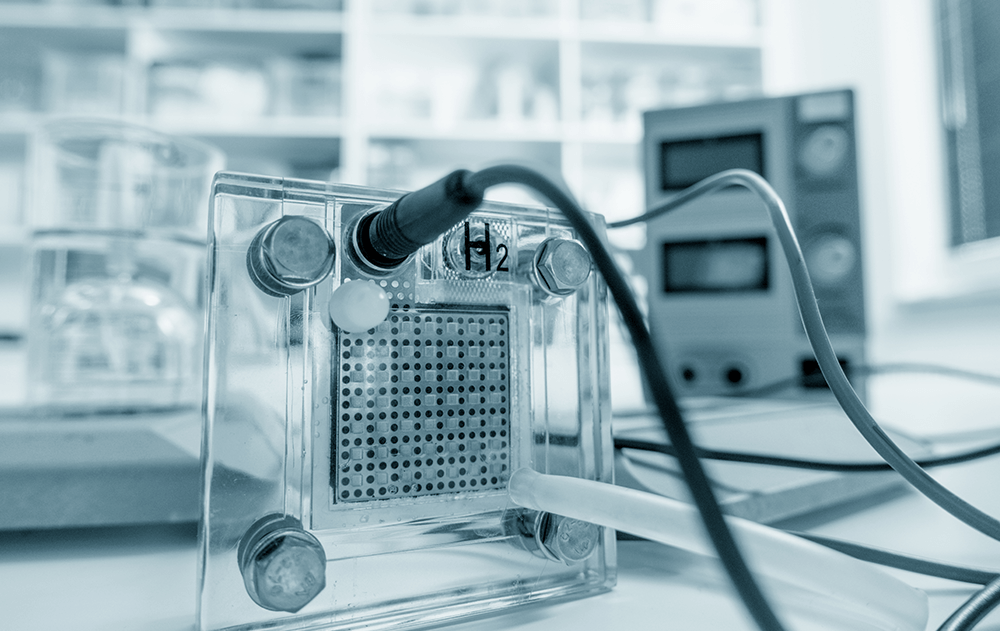

Due to its high power output and energy density, it is used, for example, in heavy-duty vehicles, machines or aircraft. The automotive industry is also striving for market-ready fuel cell solutions for light commercial vehicles.

A fuel cell stack is characterised based on performance and durability tests. Polarisation and power density curves are an important indicator of the performance of a fuel cell. Accordingly, load tests must take into account different current and resistance profiles. In the durability test (ageing test), the stack is subject to a continuous repetition of the duty cycle to ensure product stability. This can involve long testing times. Regenerative test systems are coming into focus to save energy and operating costs.

The testing of fuel cells requires an adaptable test system to cover the test requirements in the high-current and high-voltage range if necessary. If, on the other hand, the operating voltage of a single fuel cell is in the low-voltage range, the test system should still deliver precise results and be designed for a high current.

Bidirectional DC power supplies and electronic DC loads are core elements in the test bench for fuel cells and stacks. Resistance functions allow dynamic load tests under different load conditions. The user can also define a constant target resistance to draw a desired current from the stack. To check non-linear output characteristics, a charging current can be defined as a function of the voltage via an integrated XY function generator. Accelerated test profiles (step-shaped or triangular) shorten the test time.

Electronic products are becoming increasingly complex and test engineers are accordingly required to provide performance and cost-optimised test systems. At the same time, the use of highly complex measuring and testing equipment must not jeopardise the tight schedules leading up to the product launch. Ideally, your test solution should be scalable and also cover future measurement requirements in the long term.

In order to remain competitive, test processes are therefore increasingly automated. Automatic tests are not only faster, more comprehensive and more efficient than manual tests. They are also reproducible and the electronically recorded measurement data is immediately available for analysis purposes.

Automated tests also rule out application errors. Test teams can thus meet the increasing demands on their test environment while ensuring product quality, high test throughput and in-house profitability.

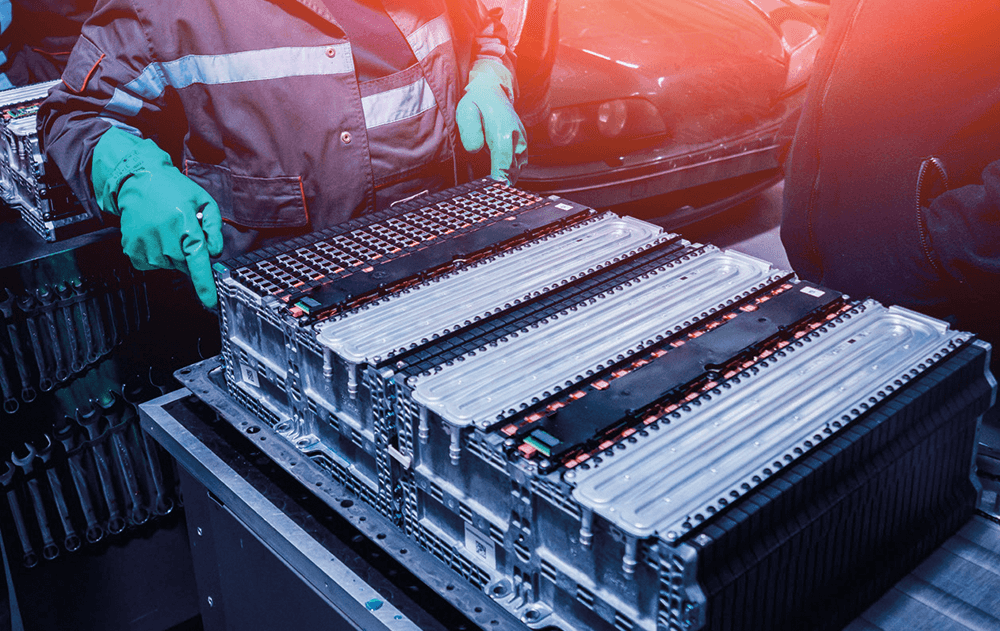

The demanding criteria regarding power density and stability ultimately apply to all battery systems. Unbalanced battery cells can reduce overall capacity and damage a battery pack. A well-functioning battery management system (BMS) is fundamental to counteract the divergence of cell voltages. The hardware and algorithms of the BMS must be validated accordingly.

The test method used requires precise, reproducible measurement results and the test environment must be safe for the user and the DUT.

Batteries also interact with the connected electronic system and influence its power consumption. In order to compare the test conditions with real battery characteristics, the electronic components must be supplied with a suitable DC source during the design phase. Last but not least, precise characterisation of quiescent current and current peaks is essential for optimum battery operating time.

A battery cell simulator is used in the development, functional testing and fault simulation of today's BMS. The electrical emulation of virtual battery cells with all relevant operating states provides automated, reproducible and safe test conditions.

For rapid product verification, the simulator can be integrated into a fully functional BMS. Precise voltage control allows unambiguous charging states of a cell to be simulated even at high currents, e. g. for balancing tests.

dataTec supports your measurement tasks – from validating a battery management system through to testing of battery-powered devices for wireless communication. With innovative battery cell simulators, battery test systems as well as bidirectional DC sources with battery simulation function (power supplies and SMU).

The increased importance of electric vehicles (EV) and hybrid EVs presents the automotive industry with complex requirements for battery storage and optimally coordinated charging and battery management. The battery system should not only work reliably and safely, but also achieve the greatest possible range, minimum charging time and maximum life span.

Especially when testing high-voltage batteries, the focus is on aspects such as battery capacity, EMI interference effects and safety.

Modern measurement technology is therefore indispensable for battery pack and chip manufacturers, algorithm developers for balancing processes, certification laboratories or for vehicle manufacturers who carry out a functional test before the final BMS integration in order to safely and efficiently characterise the infrastructure parts of the electric powertrain in EVs and HEVs.

The demanding criteria regarding power density and stability ultimately apply to all battery systems. Unbalanced battery cells can reduce overall capacity and damage a battery pack. A well-functioning battery management system (BMS) is fundamental to counteract the divergence of cell voltages. The hardware and algorithms of the BMS must be validated accordingly.

The test method used requires precise, reproducible measurement results and the test environment must be safe for the user and the DUT.

Batteries also interact with the connected electronic system and influence its power consumption. In order to compare the test conditions with real battery characteristics, the electronic components must be supplied with a suitable DC source during the design phase. Last but not least, precise characterisation of quiescent current and current peaks is essential for optimum battery operating time.

A battery cell simulator is used in the development, functional testing and fault simulation of today's BMS. The electrical emulation of virtual battery cells with all relevant operating states provides automated, reproducible and safe test conditions.

For rapid product verification, the simulator can be integrated into a fully functional BMS. Precise voltage control allows unambiguous charging states of a cell to be simulated even at high currents, e. g. for balancing tests.

dataTec supports your measurement tasks – from validating a battery management system through to testing of battery-powered devices for wireless communication. With innovative battery cell simulators, battery test systems as well as bidirectional DC sources with battery simulation function (power supplies and SMU).

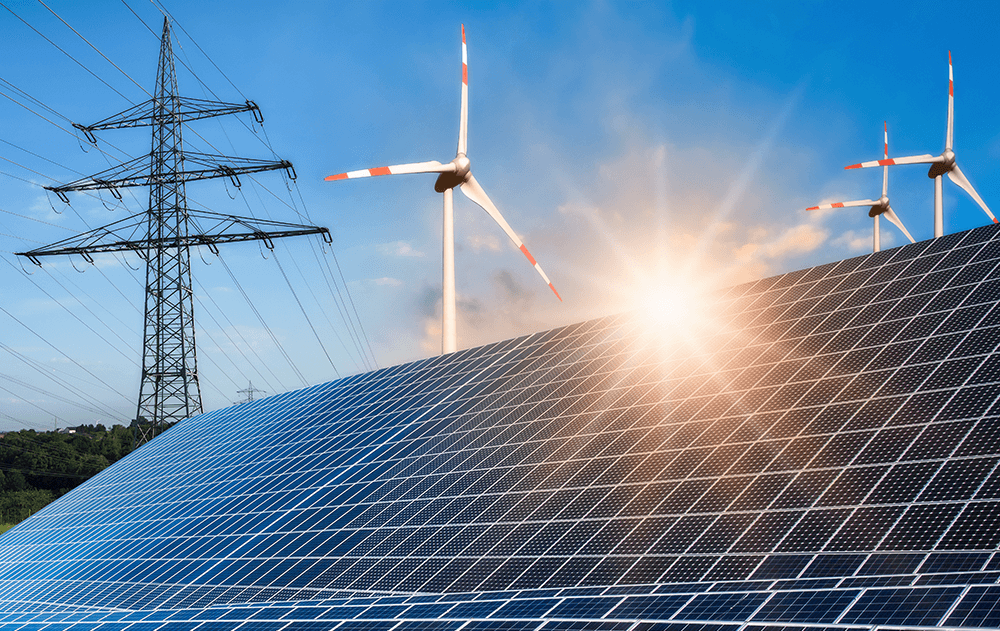

Optimum power distribution between the energy system, integrated battery storage, consumers and the public grid is just as relevant for domestic systems as it is for a smart grid.

The general cost pressure on electronic designs is driving the development of new technologies and the need for appropriate validation testing. The increasing use of high-performance components is changing aspects with regard to economic efficiency and safety.

Power converters must already be tested during development and before production release in order to detect design errors at an early stage as well as to guarantee the legal EMC specifications. Efficiency is one of the central measurement tasks.

With the increasing use of high-voltage converters (especially in electric vehicles), the demand for electromagnetic immunity is also rising. Testing in a high power environment focuses on separate safety and environmental concepts due to the high voltages and currents involved. Regulatory tests according to various standards, e. g. IEC 62116 or IEC 61000, ensure the safe operation of electronic components connected to the public power grid.

The verification of PV inverters therefore requires measurement and analysis functions that take into account different grid characteristics, voltage distortions and frequency deviations.

Our complete solution for testing PV inverters is a grid simulator consisting of a DC/AC power supply unit, a power analyser and an AC load.

This test solution from Chroma allows the performance characteristics of solar modules as well as different power grid scenarios to be simulated.

Chroma's regenerative grid simulators with grid line disturbance function simulate voltage distortions and various transient conditions for product validation of PV systems or electric vehicles.

The measurement and analysis functions are designed for pre-compliance testing. The surplus energy emitted by the device under test is fed back into the supply network in a low-loss and environmentally friendly manner.

Sie sind sich noch nicht ganz sicher oder haben weitere Fragen zu den Geräten? Zögern Sie nicht uns zu kontaktieren. Ob direkt am Telefon oder per Online-Demo bequem bei Ihnen vor dem Bildschirm – Unsere Experten sind für Sie da.