#statusMessage#

Do you want to start the compare now?

#statusMessage#

Do you want to start the compare now?

Electric vehicles are the future - but what happens to the batteries when they can no longer be used in cars? Efficient ...

For electricians, precision, safety, and efficiency are essential every day. This brochure presents a carefully selected...

Manufacturer number: PSI10060-602U

| AC input: | 110 V - 240 V |

|---|---|

| Additional functions: | Function generator with arbitrary function Simulation of solar cells and fuel cells Maximum Power Point Tracking (MPPT) Control mode CV, CC, CP, CR TFT - touch function |

| Article number: | 06230840 |

| Autorange: | Yes |

| Bidirectional: | No |

| Dimensions (L x W x H) (mm): | 462 x 482.6 x 88.9 |

| Interfaces: | USB, Ethernet, Analog |

| Model: | PSI10060-602U |

| Output power (W): | 1500 |

| Power factor: | > 0,99 |

| Protective devices: | OVP, OCP, OPP, OTP |

| Warranty (years): | 2 |

| Weight (kg): | 9.5 |

| max. Power (A): | 60 |

| max. voltage (V): | 60 |

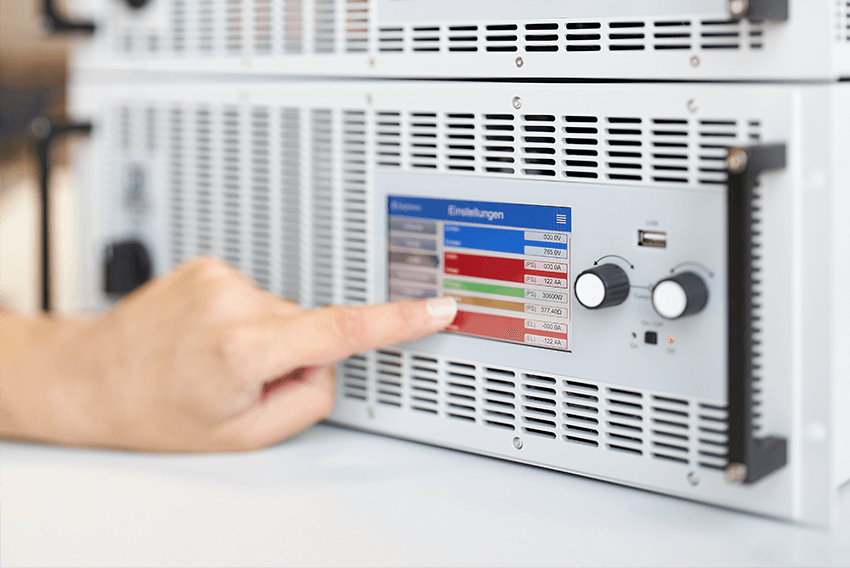

The DC laboratory power supplies of the EA Elektro-Automatik PSI 10000 series convert mains energy into a regulated DC voltage with an efficiency of over 96%. The PSI 10000 series includes single-phase and three-phase power supplies that, with their wide input range, can serve almost all mains voltages worldwide. The DC voltages and currents are oriented to the application, the spectrum ranges from 0 - 10 V to 0 - 2000 V and from 0 - 6 A to 0 - 1000 A in one device. The DC power supplies act as a flexible output stage with a constant performance characteristic, the so-called autoranging, as well as a large voltage, current and power range. In order to achieve higher power and currents, all devices have a master-slave bus. With 64 power supply units connected in parallel, this enables a system to be set up that provides up to 1920 kW and 64000 A. This system works like a single device and can consist of different power classes, only the voltage class must match.

A function generator is integrated in all models of the PSI 10000 series. This can be used to call up curves such as sine, triangle, rectangle and trapezoid in the simplest way. Voltage and current curves are freely programmable via a ramp function and an arbitrary generator. Test sequences can be saved for recurring tests and reloaded if necessary, saving valuable time.

By default, the EA power supplies are equipped with the most important digital and analogue interfaces, which are also galvanically isolated. This includes an analog interface that has configurable inputs and outputs with 0-5 V or 0-10 V for voltage, current, power and resistance, various functional inputs and outputs as well as a USB and Ethernet interface each.

The power supplies of the PSI 10000 series are ideal for relay tests in which the coils of DC relays and the contacts have to be supplied with precisely defined voltages and currents. When testing the coils, important parameters such as response, operating, holding and dropout currents as well as the associated voltages must be checked and documented. Not only the current carrying capacity and the contact resistance are important parameters for the contacts, but also the dielectric strength and breaking capacity say a lot about the quality of the products.

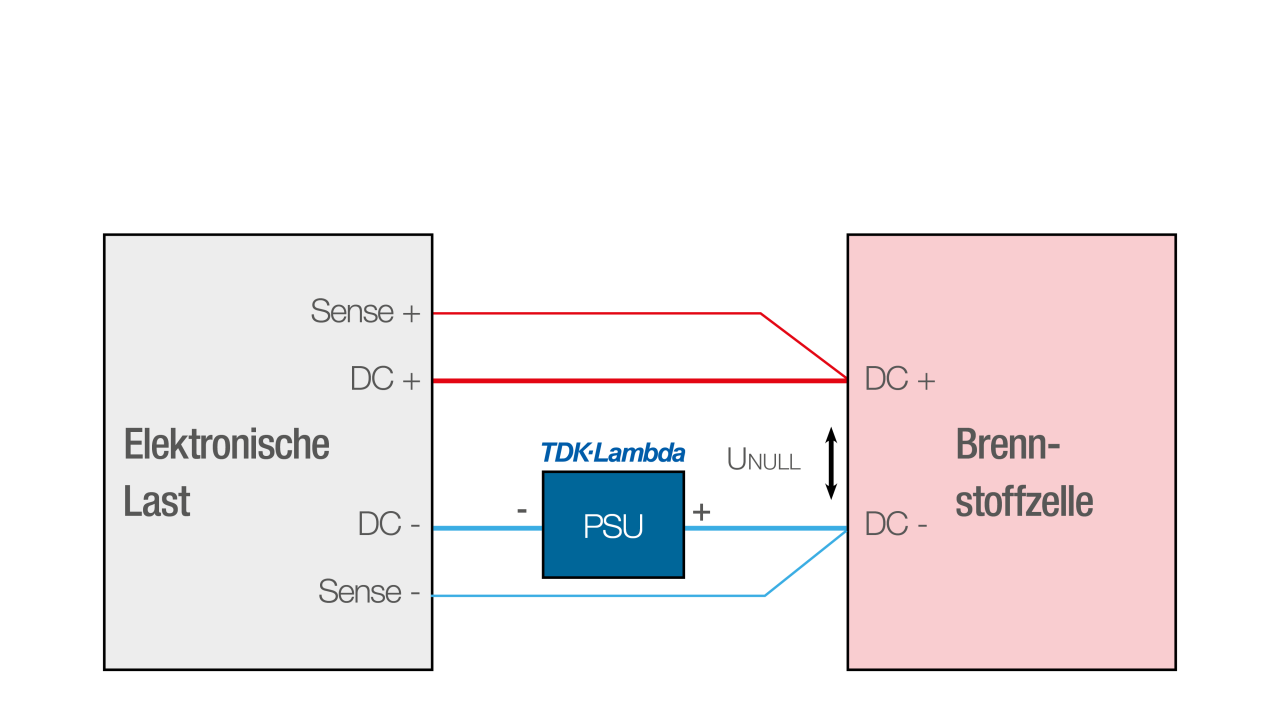

Furthermore, the PSI 10000 power supplies are ideally suited for simulating fuel cells. With the help of these simulations, both the energy storage device and the components that are supplied by it can be optimally designed. Wherever reproducible data is required, working with a simulator is the first choice. In addition, when using the simulator as a supply source, various protective mechanisms are in effect to protect the connected consumer.

The PSI 10000 are also suitable for on-board charger tests (OBC). Here the OBC has to be tested for its electrical properties under various conditions. This requires a flexible test system that also provides measurement data. With the sequencing & logging function, test sequences can be loaded into the PS 10000 devices and data can be read out and saved.

The programmable power supplies of the PSI 10000 series are ideal as test systems for PV inverters because they have the necessary simulation unit for solar cells. Users can quickly and easily program their simulation models according to EN 50530 or Sandia and use the properties of a wide variety of solar cell materials.

The variant PSI 10060-60 of the EA PSI10000 series presented here measures 2 HE (2U) and has a 0 - 60 V voltage, 0 - 60 A current, 0 - 1,500 W power and, like all models of the PSI 10000 series, a integrated function generator.

Electric vehicles are the future - but what happens to the batteries when they can no longer be used in cars? Efficient ...

Due to an unavoidable minimum internal resistance - the so-called RDS(on) (minimum on-resistance of the FET between drai...

With the worldwide effort to increase energy conservation and reduce fossil fuel use, electrification is occurring at a ...

With the increasing importance of renewable energies in the wake of climate change, solar energy is moving further into ...

Power supply units are as diverse as their areas of application. What do you personally use your power supply unit for? ...